IABG History

Milestones in our company history

Opening Mobility Innovation Campus (MIC)

Together with the Technical University of Munich, we have set up a test field for intelligent mobility concepts - the Mobility Innovation Campus. Automated and networked transport systems and their safe operation are being researched here.

Competence Centre Optics (CCO) starts operation

In our Center of Competence Optics (CCO), which is unique in Europe, we carry out development and qualification tests on earth observation satellites and electro-optical systems for space applications. Its strategic importance ranges from supporting projects for scientific environmental monitoring to security-related programs.

Competence Centre Optics

New Test Centre for H2 Technologies

Hydrogen technologies play a central role in the energy transition. IABG tests and qualifies these technologies at its sites in Lichtenau (tests with cryogas) and Dresden (water-hydraulic tests).

Opening Competence Centre Marine in Hamburg

The opening of our new office in Hamburg offers valuable opportunities to strengthen our collaboration with authorities, academia, and industry in the maritime domain.

IABG hands over large test bench MAXI to the German Armed Forces

The globally unique, multiaxial test bench for wheeled land vehicles (MAXI) was handed over to the German Armed Forces in May 2022. In its role as general contractor, IABG built the turnkey test bench.

Centre for the qualification of rail vehicles in Dresden

IABG has been qualifying complex systems in the automotive and aerospace sectors for many years. Since 2021, we have also been offering these services for the rail industry and are opening our new test centre in Dresden for this purpose.

Establishment of the Competence Centre for Artificial Intelligence (AI)

We are responding to the increasing importance of AI in all sectors and areas of technology with our own competence centre for AI.

Establishment of the IABG Innovation Centre

The Innovation Centre still serves as an incubator for the future service portfolio with a focus on digitalisation, data science, AI and networked, electric, autonomous systems.

Structural tests on the Airbus A350

A new test infrastructure is being set up in Erding for structural tests on the Airbus A350.

Schwarz Holding GmbH takes over the management of the company

SCHWARZ Holding GmbH takes over the shares of IABG as majority shareholder. IABG thus becomes an owner-managed company.

Opening of Geodata Factory in Dresden

The demand for geodata for civil and military clients is constantly increasing. IABG is responding with a competence centre for geodata and geoinformation and today employs over 50 experts for the collection, processing, analysis and visualisation of such data.

Relocation to the new technology centre

A large part of the workforce moves to the new technology centre, in conjunction with the relocation of IABG from Ottobrunn to Taufkirchen.

New test infrastructure for large-scale aircraft tests in Dresden / Fatigue test on the Airbus 380

Carrying out structural load tests on the prototype of the largest civilian commercial aircraft ever produced in series. After being commissioned to carry out tests on the Airbus A380 in 2002, a new test hangar was built on the grounds of Dresden Airport. The world's largest fatigue test began in September 2005, during which 47,500 flights were simulated.

S & D Industriebeteiligungen GmbH takes over the entrepreneurial management

S & D Industriebeteiligungen GmbH takes over the shares held by TRW and IVG and thus the entrepreneurial management of IABG.

Commissioning of the new acoustic laboratory

Commissioning of the new acoutic laboratory integrated into the space centre.

Foundation of European Testing Services B.V. (ETS)

50 % stake in ETS. This company operates ESTEC's space test facilities in Nordwijk (NL).

Foundation of IABG Mitarbeiterbeteiligungs AG

IABG MBAG holds a minority interest in IABG. It was founded with the aim of enabling IABG employees to participate indirectly in the company.

Privatisation of the company

Privatisation of the company by the Federal Republic of Germany: BDM International Inc. takes over the entrepreneurial management as the main shareholder.

Foundation of the "Environment" business segment

In 1991, the Federal Ministry for the Environment commissioned IABG and 20 partner companies with the “Investigation of suspected contaminated sites on the properties of the Western Group of Soviet Troops (WGT)”. This major contract established IABG's new “Environment” business segment.

Establishment of the "InfoKom" business segment

With the beginning of the “digital revolution” (Internet) in the 1990s, the “InfoKom” business segment was established. Even then, we were able to draw on the expertise of over 400 IT experts.

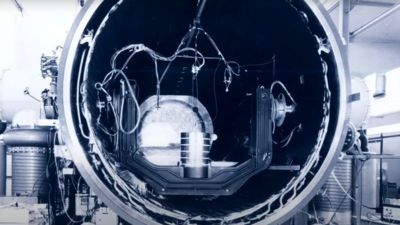

Opening of the new space simulation facility

The tests on the planned Franco-German television satellite ‘TV-SAT’ made a new, larger space simulation chamber necessary. After a three-year planning and construction period, it went into operation in autumn 1983. The chamber enabled qualification tests to be carried out on complete satellites under simulated space conditions such as vacuum, ultra-low temperatures and solar radiation.

Start of operation of the Transrapid test facility in Lathen/Emsland

The magnetic railway test facility was operated by IABG (from 1985 by the Versuchs- und Planungsgesellschaft für Magnetbahnsysteme, a subsidiary of the then Deutsche Bundesbahn and Lufthansa). It served as a track for the development and testing of Transrapid trains. The facility was decommissioned at the end of 2011 and part of the site is now used as a research centre for electromobility.

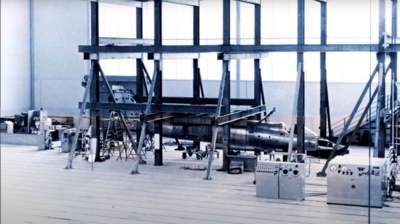

Full Scale test on the MRCA Tornado

Germany, Italy and Great Britain joined forces to develop a successor to the “Starfighter” aircraft. The then ultra-modern and extremely flexible multi-role combat aircraft (MRCA) was tested at IABG. The Tornado was the most important military aircraft type in Western Europe for decades, and the test rig at IABG was only dismantled at the beginning of the 2020s.

New automotive business segment

The introduction of emission limits in the USA triggered the need for testing in the German (export-dependent) automotive industry. With its testing facilities, IABG was able to transfer its unique expertise in testing from the aerospace industry to the automotive sector and became a trusted partner of car manufacturers.

First large-scale aircraft test on the Airbus A300

In September 1967, the governments of France, Great Britain and Germany signed a memorandum in which they decided to develop a twin-engine wide-body aircraft. The background to the project was the desire to create a European counterweight to American supremacy in aeronautics. Six years later, the Airbus A300 B was tested for strength and durability at IABG.

Commissioning of the space test centre

The way had already been paved for the establishment of a national space test centre in 1963. In September 1965, Federal Chancellor Ludwig Erhard (CDU) and MdB Konstantin Prinz von Bayern (CSU) visited IABG to discuss the development of a European launch vehicle ("Europa"), which would later become the forerunner of the famous “Ariane”. The space simulation facility was built for the necessary tests, which signalled the company's entry into the space business.

Development of Operations Research (OR)

From the very beginning, one of IABG's most important tasks was the development of security and defence analyses for the Bundeswehr. To this end, operations research methods were used to support decision-making processes. This laid the foundation for the “Defence and Security” business segment.

Foundation of the company

Foundation of Industrieanlagen-Betriebsgesellschaft mbH (IABG) by the Federal Republic of Germany as a central facility for aerospace testing and defence analysis.

How can we help you?

Please fill in the form and we will get in touch with you as soon as possible.