Characterization of Fatigue Behavior (LCF, HCF, TMF)

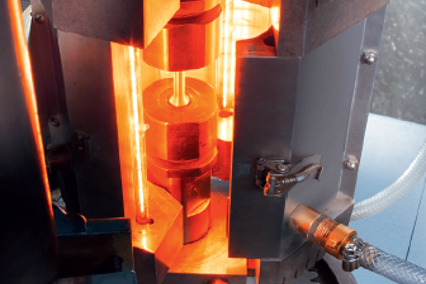

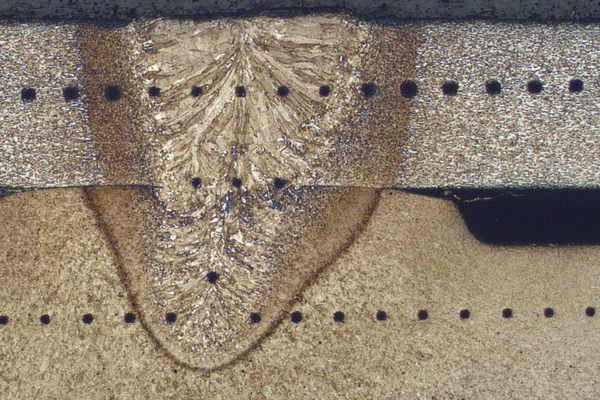

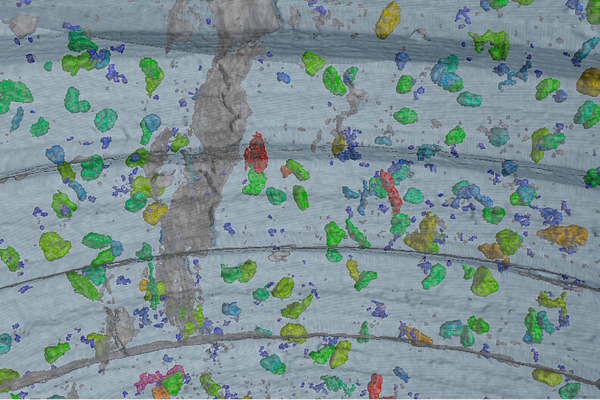

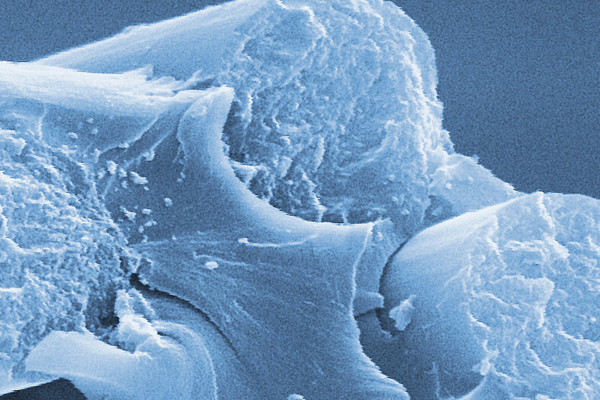

When describing the fatigue behavior using Wöhler curves, we basically differentiate between strain-controlled tests in the short-term strength range (LCF) and stress-controlled tests in the long-term strength range (HCF). The application of mechanical stresses and plastic strains through strain restraints at a controlled temperature corresponds to a thermomechanical fatigue test (TMF).

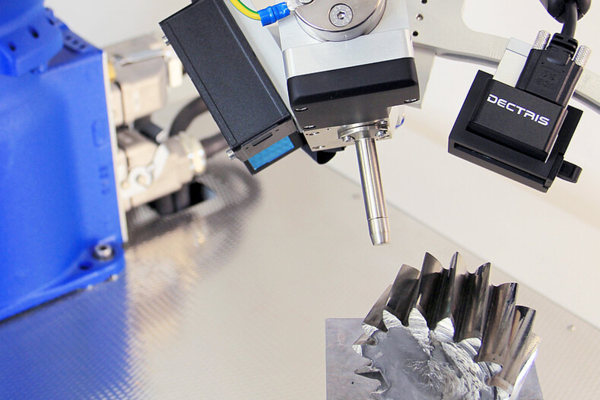

We can realize test loads between 500 N - 100 kN, test frequencies up to 130 Hz and test temperatures in the range between -196 °C and +900 °C.

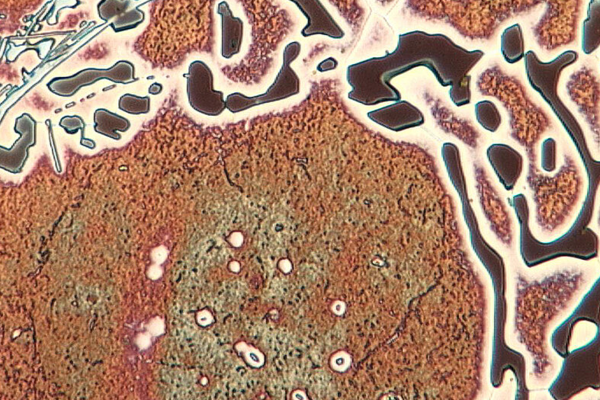

Low cycle fatigue (LCF) testing: strain-controlled tests in accordance with ASTM E606 or ISO12106 and fatigue testing with a wide range of load types (tension, compression, shear)

Investigation of High Cycle Fatigue (HCF): Stress-controlled tests according to DIN50100, testing with a wide variety of load types (tension, compression, shear)

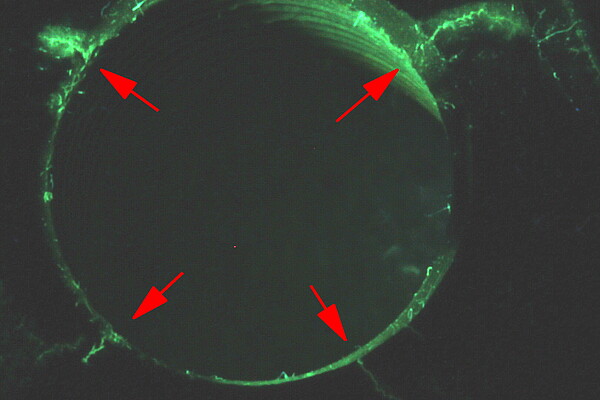

Investigation of thermo-mechanical fatigue (TMF):

- Mapping of combined cyclic thermal and mechanical loads

- Independent control for the application of cyclic thermal and mechanical loads

- Heating/cooling rates of 5 K/s

- Testing in accordance with the "Validated Code of Practice for Strain-Controlled Thermo-Mechanical Fatigue Testing"