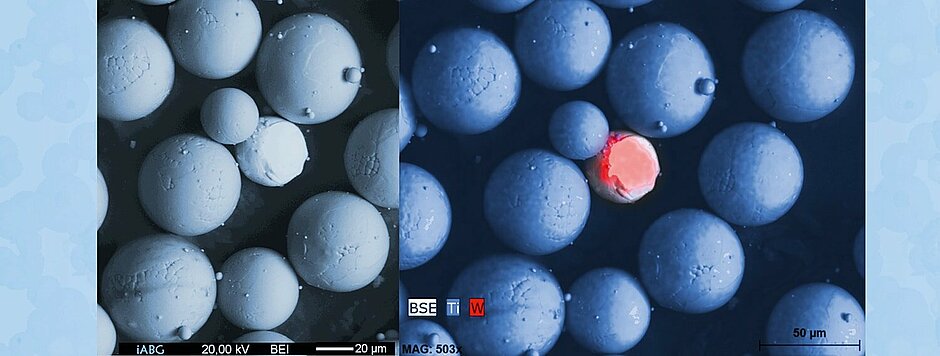

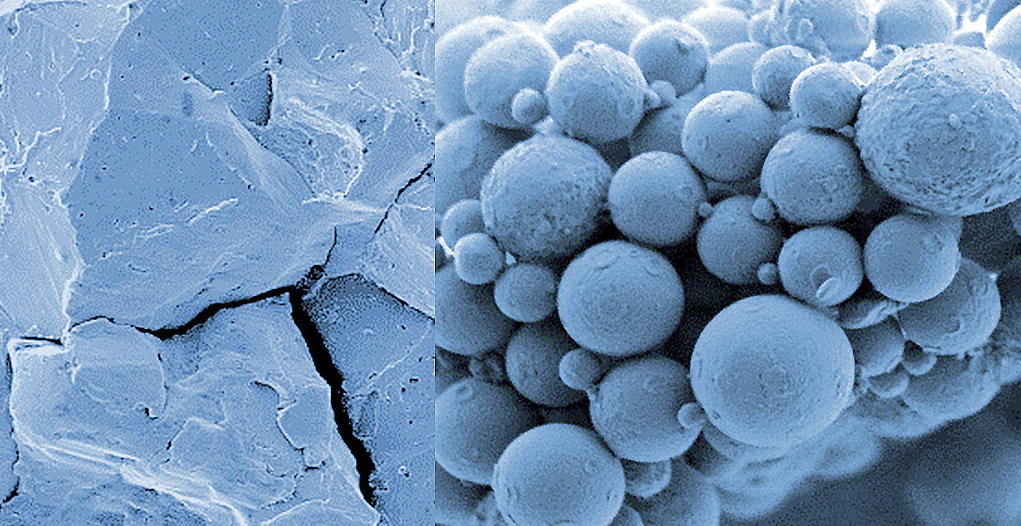

Macroscopic examination

The visual inspection allows a quick and extremely efficient detection of gross anomalies in the powder material. The following properties are compared with specified criteria to enable efficient evaluation:

- Coatings

- Moisture content

- Coarseness

- contamination