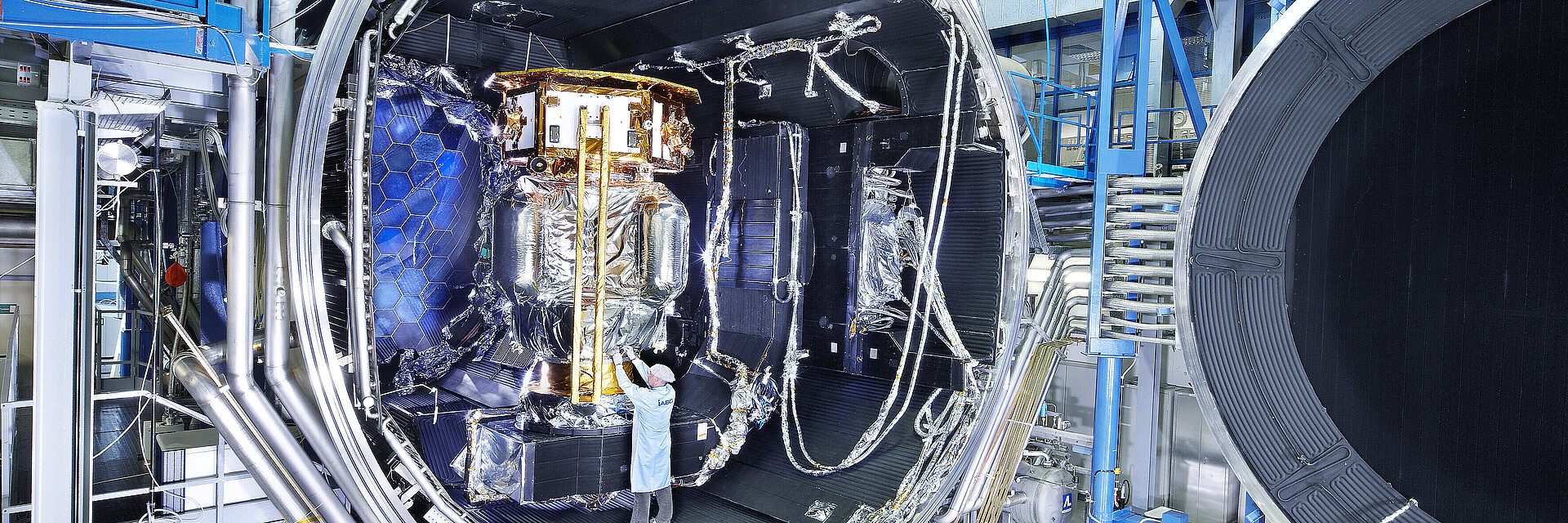

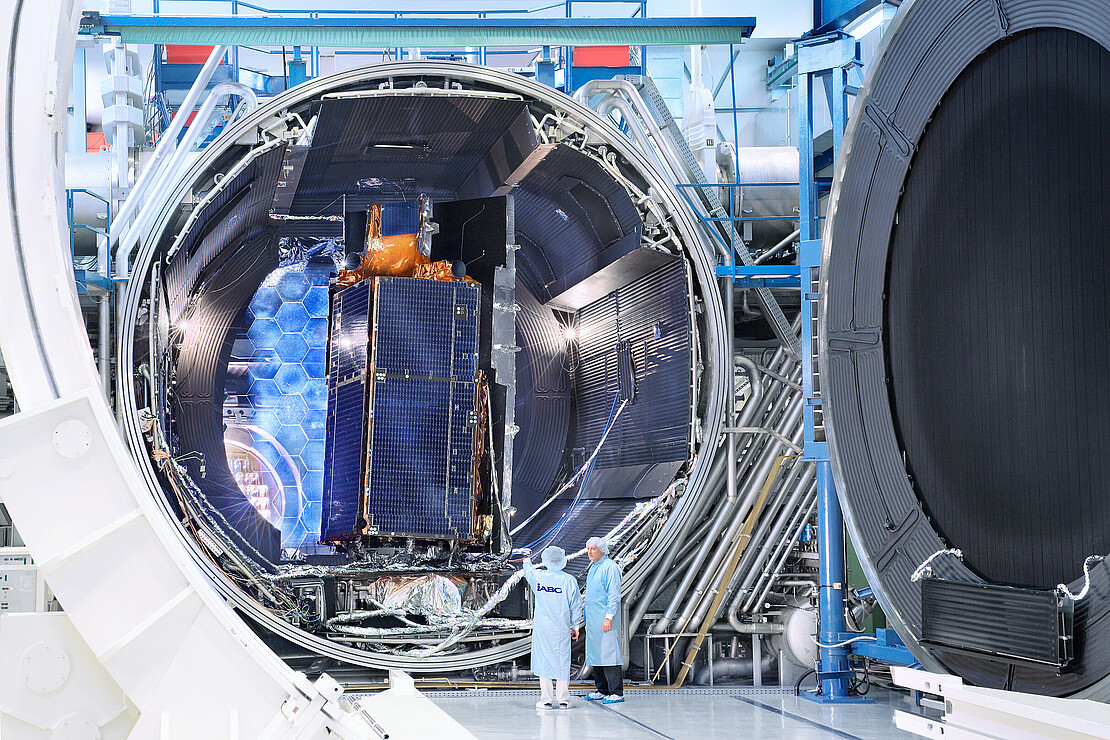

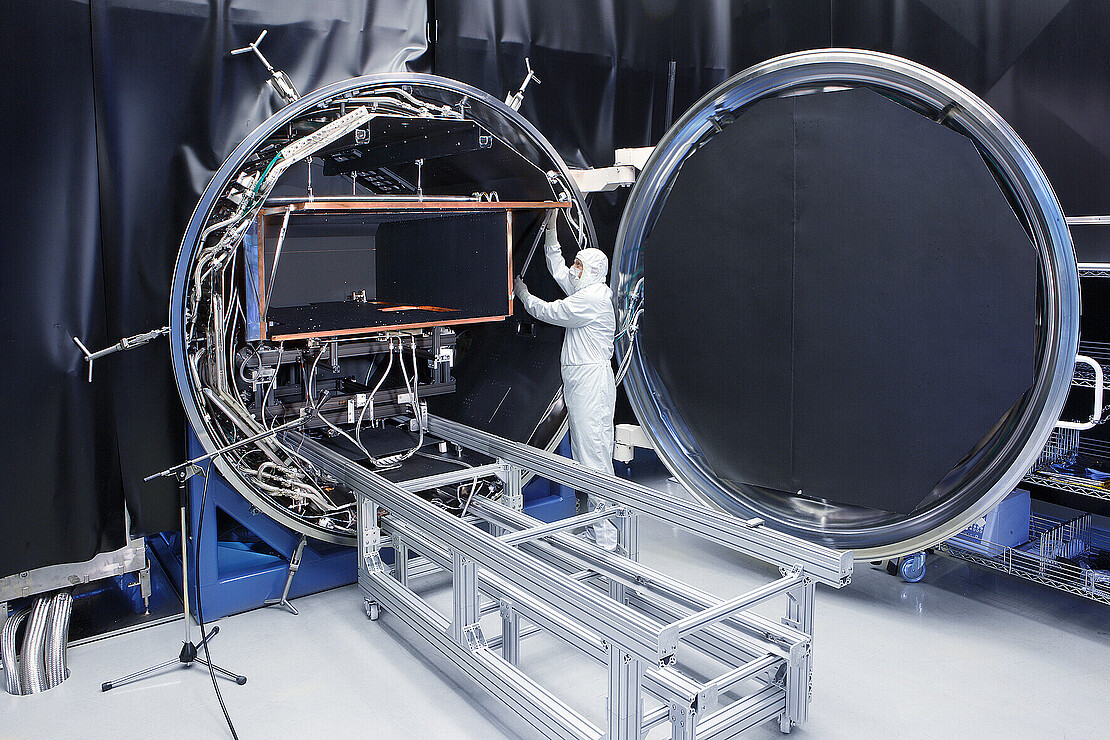

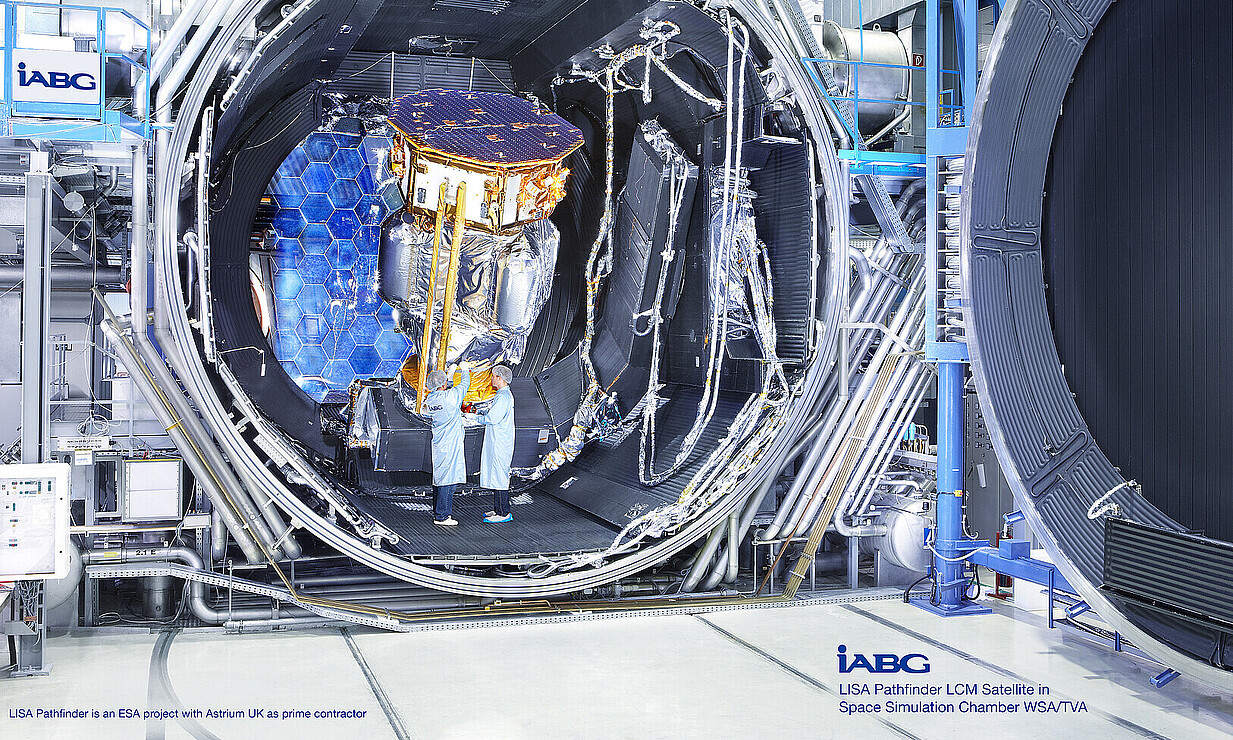

Thermal Vacuum Chambers

Performance Spectrum of Our Thermal Vacuum Chambers

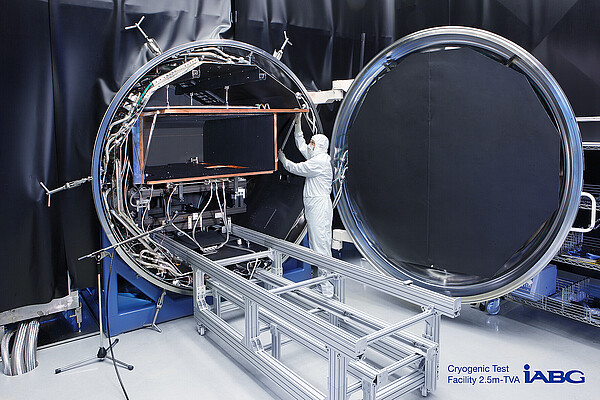

(WSA, 5 m TVA, 3 m TVA, 2.5 m HeTVA, 2 m TVA)

- Simulation of space conditions: High vacuum, low background temperature (LN2)

- Clean room standards ISO 8 and ISO 5 (5m TVA & 2.5m HeTVA)

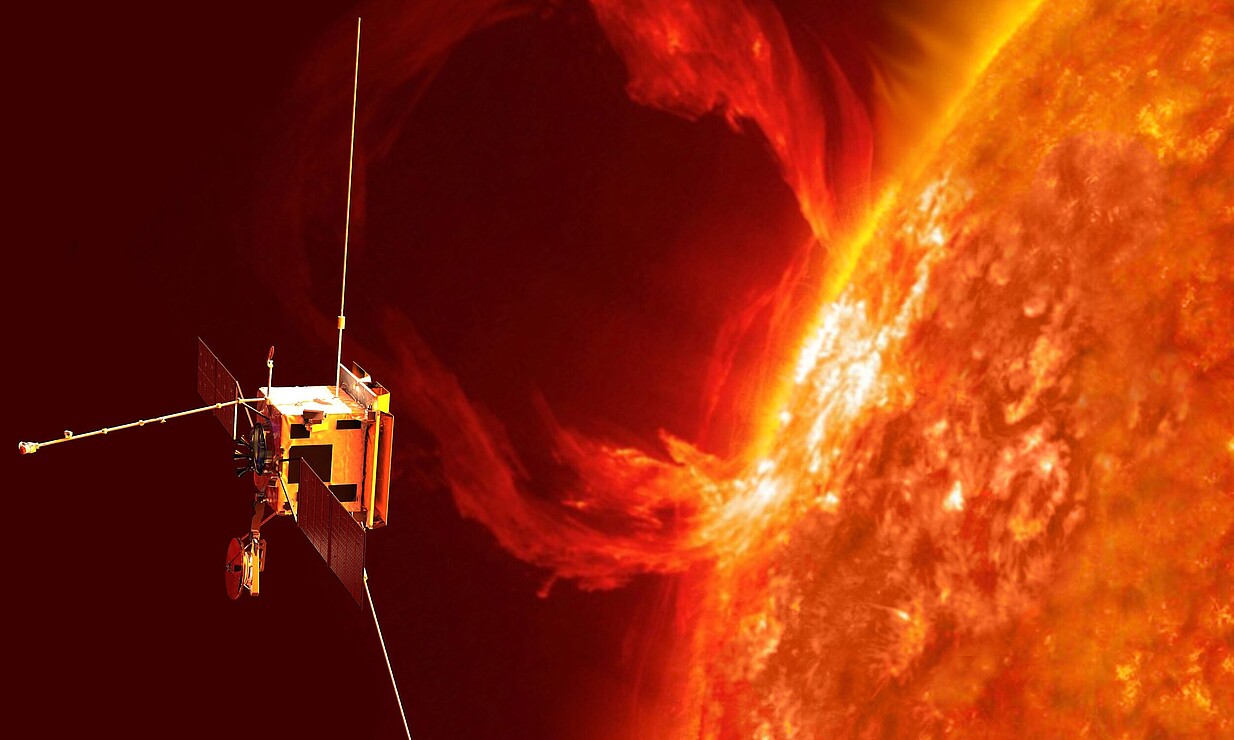

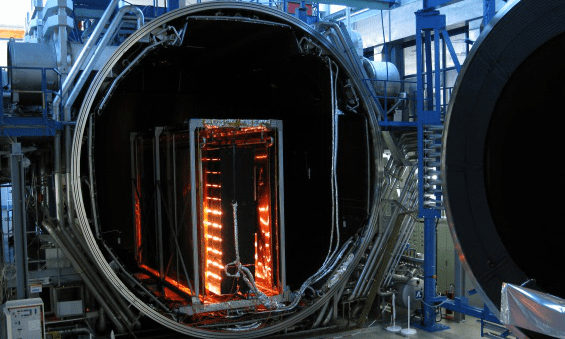

- Artificial solar radiation generation with xenon lamps (WSA)

- Free movement of the test object relative to the solar radiation using a motion simulator (WSA)

- Micro-vibration decoupling (5m TVA)

- High-temperature (up to 700 K) and low-temperature (down to 10 K) simulations in 2.5m HeTVA

- Customized solutions and services available upon request

- Chamber diameters from approx. 2 m to over 6 m, chamber lengths from approx. 2 m to 14 m.