- Home

- Services

- Testing & Qualification

- Development & Construction of Test Systems

- Functional Test Benches

- Home

- Services

- Testing & Qualification

- Development & Construction of Test Systems

- Functional Test Benches

We Plan and Implement your Functional Test Bench

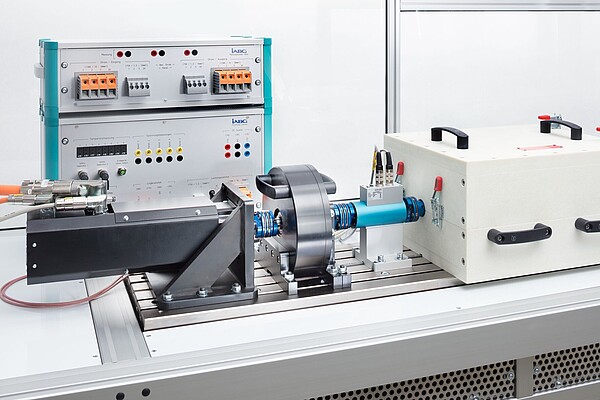

The use of mechatronic systems (e.g. electromechanical steering systems, active vehicle dynamics systems) helps resolve conflicting objectives in vehicle development, enables new functionalities and creates additional degrees of freedom for optimization. Development efforts and innovations are shifting from mechanical components to electronics and software. The development of such systems requires dedicated test benches that enable the characterization and validation of the overall mechatronic system (mechanics, electric drive, electronics and software).

Custom-built and fully automated test benches

Test benches for mechatronic systems include mechanical load units, control of test specimens via the vehicle bus (e.g. CAN, FlexRay, Ethernet) and appropriate electrical power supply (vehicle battery simulation). Different temperature and climate conditions are also frequently simulated. In principle, the higher the required safety integrity level (ASIL level) according to ISO 26262, the greater the testing effort.

The appropriate automation of functional and development test benches is crucial for the efficient development and validation of mechatronic systems. This includes synchronized operation and control of individual subsystems of the test bench and the test object via a higher-level test automation system, integration of the test bench into existing processes and tool chains and the automation of test procedures.

We therefore coordinate suitable functional architectures and interfaces as well as software and hardware modules for your specific application individually.

Flexible applications

Our functional and development test stands are typically used for development-related investigations (e.g. structure-borne noise analysis), performance tests (e.g., efficiency or friction tests) and automated functional validation of the system, including the simulation of electrical faults (e.g. short circuits or bus failures).

Automated release tests of software versions, driver-in-the-loop studies, maneuver-based testing and endurance testing are additional applications of our hardware-in-the-loop test benches. Our goal is always to develop a solution with you that provides maximum flexibility for current and future testing tasks.

Benefit from the advantages of our functional test benches:

Customized software and hardware solutions

We offer you tailored software and hardware solutions for your system test bench - customized to your specific tasks and requirements.

When designing suitable system and functional architectures, we take into account not only your standards, preferred lists and operating equipment regulations but also any existing automation solutions, processes and toolchains you already have in place. If necessary, we implement custom interfaces, such as for integrating additional peripherals, communication with higher-level automation systems or linking the test environment to your database systems.

For you, this means unified, standardized solutions in your test field, short training times, flexible personnel deployment and maximum adaptability for current and future testing tasks.

Tailored actuators and control technology

Mechatronic systems are usually characterized on the basis of differing load cases, ranging from tests in a blocked state to very slow movements at constant speed (e.g. for measuring friction forces), tracking signals from driving operation measurements and highly dynamic tests (e.g. determining step responses for controller tuning). While most tests are carried out with an active, controlled test specimen, some of these tests (e.g. determination of friction forces or determination of dynamic stiffness) are also carried out on a passive test specimen. The resulting conflicts of objectives are aggravated by the fact that test specimens with very different mechanical properties generally have to be characterized. Examples of this are component stiffnesses, transmission ratio, a wide variety of geometries and different installation positions. The different load cases and the widely varying properties of the test specimens result in a huge spectrum of differing requirements for the actuators and the control of the test bench.

In the case of active test specimens, the interactions between the control of the test stand and the control loops of the test specimens present a further challenge. Here, too, it must be taken into account that the dynamic behavior of the test specimens can vary greatly depending on the operating modes and the software version installed. Iterative approaches, which are used on test benches for conventional, passive test specimens to improve the control quality, are often unsuitable for the functional testing of electromechanical systems due to the highly time-variant behavior of the active test specimens.

We therefore design the actuators and control algorithms of your new HiL test bench based on models to meet your specific requirements. For moderate dynamic requirements, we mainly use electric servo machines with ball screw drives or energy-efficient hydrostatic drives. For even higher requirements, we primarily use electric direct drives. The latter offer significant advantages over servo-hydraulic drives, particularly in terms of performance, energy consumption, operating and maintenance costs, the realization of safe operating states (e.g. for set-up) and the required infrastructure.

Reliable test results across the entire range of applications

It goes without saying that functional test benches have to perform significantly better than the test specimens. This results in high demands on dynamics, measurement accuracy, rigidity and structural dynamic behavior. The design of rigid structures is often made more difficult by large set-up and adjustment ranges. These are necessary in order to enable a wide variety of geometries and mounting positions of the test specimens.

With our expertise, we design your system test bench using various numerical tools to precisely meet your individual requirements. We identify potential conflicts of interest, discuss them with you and suggest suitable solutions.

The result: a test system that fulfils your individual requirements and delivers test results you can rely on.

Variability and expandability

New development projects often require the procurement of new test systems. As the conceptualization and design of the test systems usually begins in early development phases of the test specimen, the requirements for the functional test benches are often still unclear at the start of development or change during the course of the project. This is aggravated by the fact that, due to the high level of investment, sufficient performance reserves must be held in reserve for future product generations with as yet unknown properties.

This can be achieved through partnership-based cooperation in the projects and professional requirements management. Our aim is to work with you to develop the optimum solution for your task, to take contingencies into account and to provide for expansion options.

For you, this means investment security.

Easy and safe operation

We implement the test automation of your test bench according to your specific requirements. We develop the user interfaces required for this together with you during the project. It goes without saying that we take the future users and your in-house experience into account. With the aim of enabling simple, fast, safe and ergonomic set-up, we develop suitable set-up concepts - also together with you or the future operators. We coordinate the safety concept of the test bench with the users and your occupational safety department at an early stage. Where possible, we use actuators with proven and easy-to-implement safety functions.

The result is test benches that are simple and safe to operate.

How can we help you?

Please fill in the form and we will get in touch with you as soon as possible.