Thermo-Mechanical Fatigue of Cylinder Heads

Task

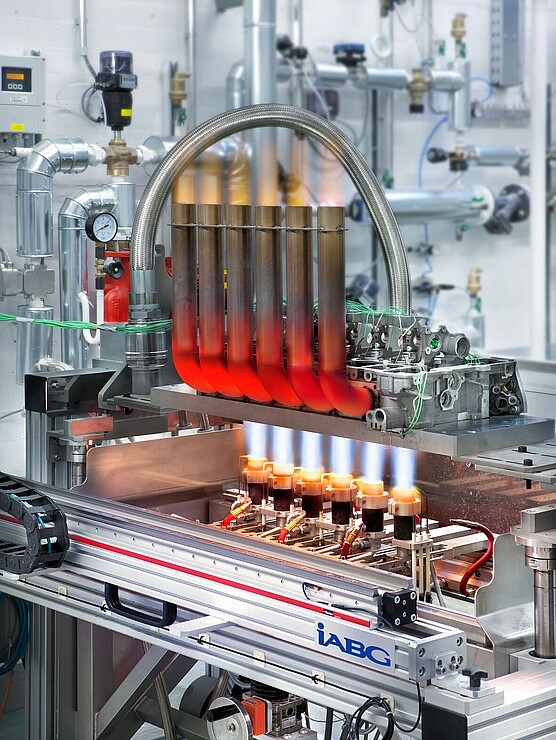

The cylinder head test rig enables the accelerated simulation of thermal stress cycles on cylinder heads in the lab, providing proof of operational durability against thermo-mechanical fatigue.

Test bench

IABG operates two cylinder head test rigs that simulate thermal cyclic loads on the combustion chamber roof. The core of both facilities consists of burner units powered by a propane-oxygen mixture. Each rig has six independently adjustable burners, allowing cylinder heads of various sizes to be tested continuously at high performance levels.

Each test specimen is mounted on a crankcase substitute, which is designed and flow-optimized using computer-assisted methods to replicate the flow conditions in the cooling channels of a fired engine. The cylinder heads can be rapidly heated to operating temperature and cooled with temperature-controlled glycol-water mixtures in freely selectable and definable cycles. Two separate cooling circuits with different inlet temperatures allow for customized cooling curves.

All system components are geared towards automated continuous operation. The open setup allows for inspections during continuous testing with minimal interruptions. A digital camera system is used for crack detection and documentation. The test area is equipped with a control room, a separate assembly area and a storage room. IABG operates these test rigs, including computational design and flow optimization of adaptation parts, for customers in the automotive, energy and marine sectors.

Advantages

- Cylinder heads can be tested at a very early stage of development, without the need for a complete engine.

- Test times and costs are significantly lower compared to tests on engine endurance test benches.

- Cracks can be detected and monitored during the test using an automated camera system, allowing for quick assessment of results regarding lifespan and crack patterns, execution of variant tests and statistical validation through a high number of tests. This approach also opens new possibilities for verifying computational methods.

- The full range of passenger car and commercial vehicle engines, as well as engines from marine applications and large gas engines used in power generation, can be tested on both rigs.

- This innovative testing method addresses the increasingly shorter development cycles in the engine industry and reduces the need for extensive and costly engine endurance runs.