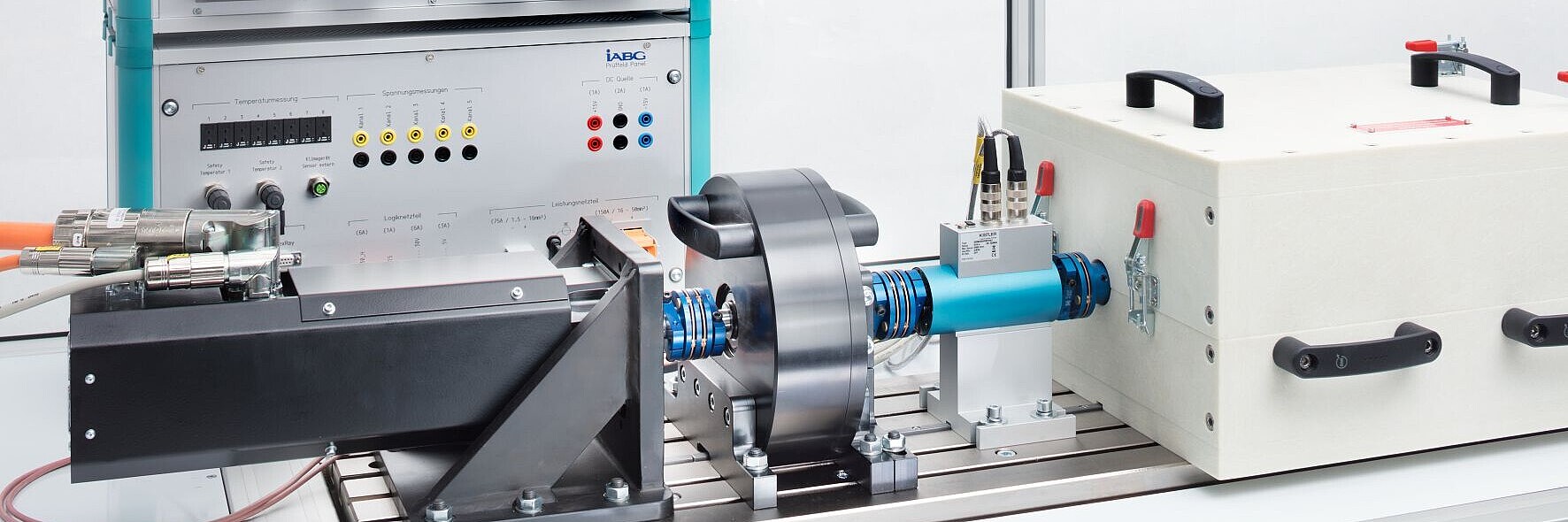

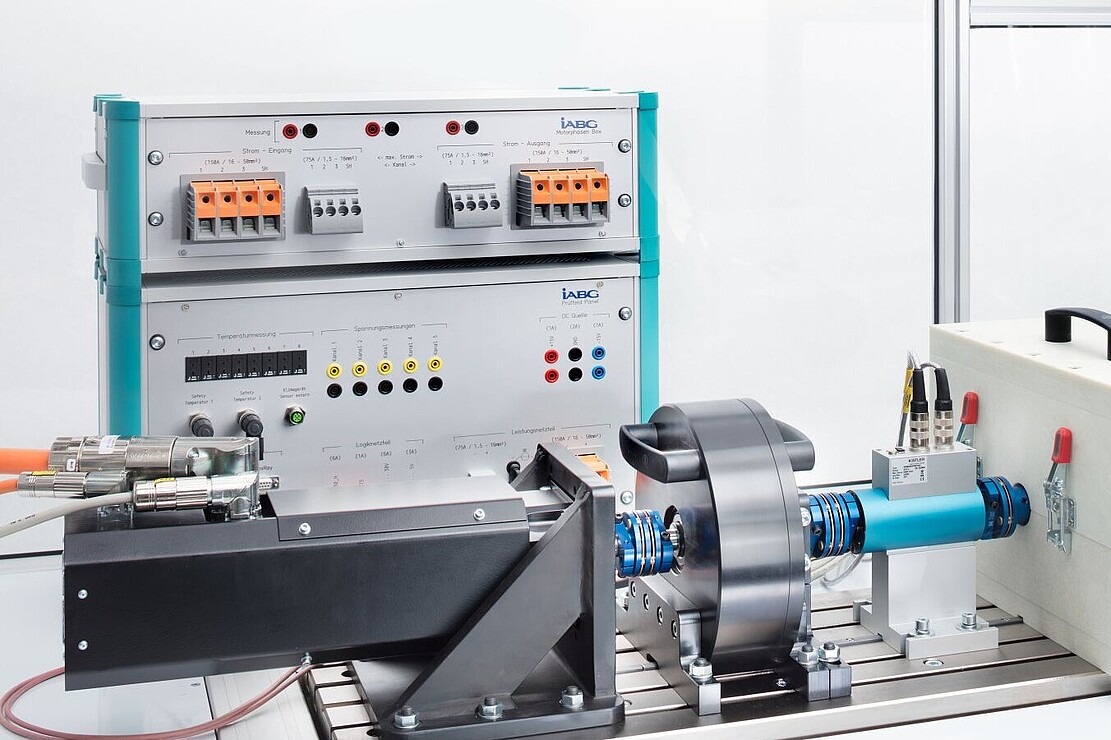

Development Test Bench for Electric Actuators

Our DC electric motor test benches are designed for the characterization of electric actuators during development and series production. The properties of electric actuators can be optimized and validated under environmental conditions.

- Safeguarding over the service life

- Characterization of electric actuators

- Safeguarding operational stability

- Quality assurance

- Identification of characteristic values under climatic conditions