The pinion actuator simulates the forces and displacements acting on the steering . It therefore significantly determines the performance and the possible application of your steering test bench.

Depending on the test cases to be modelled, there may be very different requirements for the pinion actuators and their control. For example, a high degree of synchronization at very low speeds is essential for meaningful friction force measurements on the steering gear, while dynamic drives are required for simulating driving maneuvers or determining the dynamic properties of the steering. High forces and speeds are required for availability measurements, the determination of efficiency or park tests. In turn, high dynamic and highly accurate drives with minimal latency are required for the evaluation of steering characteristics by test drivers in interaction with test benches. The selection and design of suitable actuators is therefore generally more challenging the more flexible the steering test bench is to be used.

The selection of a suitable actuator, its specification and the design of the control system is therefore model-based for the test cases to be mapped and takes into account the properties of all relevant test specimens. In addition to your specific requirements for force, speed, control accuracy, dynamic, latency and synchronization, we naturally also take into account the investment and operating costs.

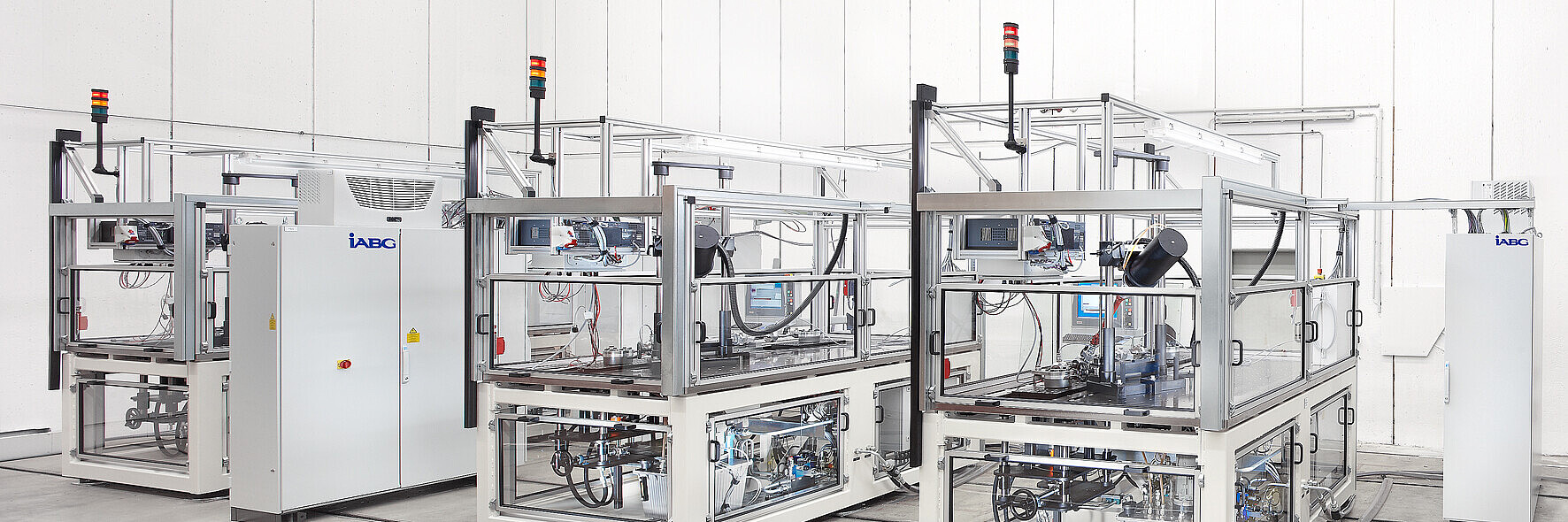

We are not bound by any operating principle. Quite the opposite: our aim is to offer you the technically and economically best actuators for your specific requirements. The spectrum ranges from spindle drives in test benches with low dynamic requirements to servo-hydraulic drives in endurance test benches and high-performance electric linear drives in high-performance steering test benches, which are used for a wide variety of testing tasks.