Model-based system development and digital twin: a highly efficient combination

When it comes to perfection, detailed planning and realistic dress rehearsals ensure that, in practice, all the action sequences are coordinated and run according to plan. The digital twin follows the same principle: virtual images of physical products enable the optimization of development, procurement and maintenance processes. Wrong decisions can be minimized and resources used optimally by simulating the entire life cycle - from development to decommissioning.

With the "turn of an era", investment in armaments is increasing significantly. However, the increasing complexity of military equipment requires new tools for controlled and efficient action. The digital twin offers this possibility: from the determination of requirements to the procurement decision through to ongoing operations.

At the heart of the digital twin is the ability to process and analyze product or process-related data in order to gain valuable insights and identify patterns. At the same time, a detailed 3D model of the physical object can be created, which is constantly updated with real-time data. This enables precise simulations of different scenarios and thus predictions about future behavior or performance.

Based on the analyses and simulations carried out, specific suggestions for improvement can be developed, which are then transferred to the physical object. These changes are in turn reflected back to the digital twin, creating a continuous improvement cycle. This constant exchange between the physical and digital worlds opens up new possibilities for increasing efficiency and innovation.

First simulate, then decide

The advantages are manifold: for example, since changes can be made virtually rather than on the physical prototype during the design phase, development cycles are drastically shortened. Requirements can be defined more precisely and immediately checked for feasibility. The technology also enables a more effective exchange of information and therefore more intensive collaboration between the military, engineers and suppliers. The strength of the digital twin is also evident in crisis situations: In the event of a rapidly changing threat situation, it is possible to analyze within a few hours how changes to equipment or tactics would affect the situation. This provides a decisive strategic advantage.

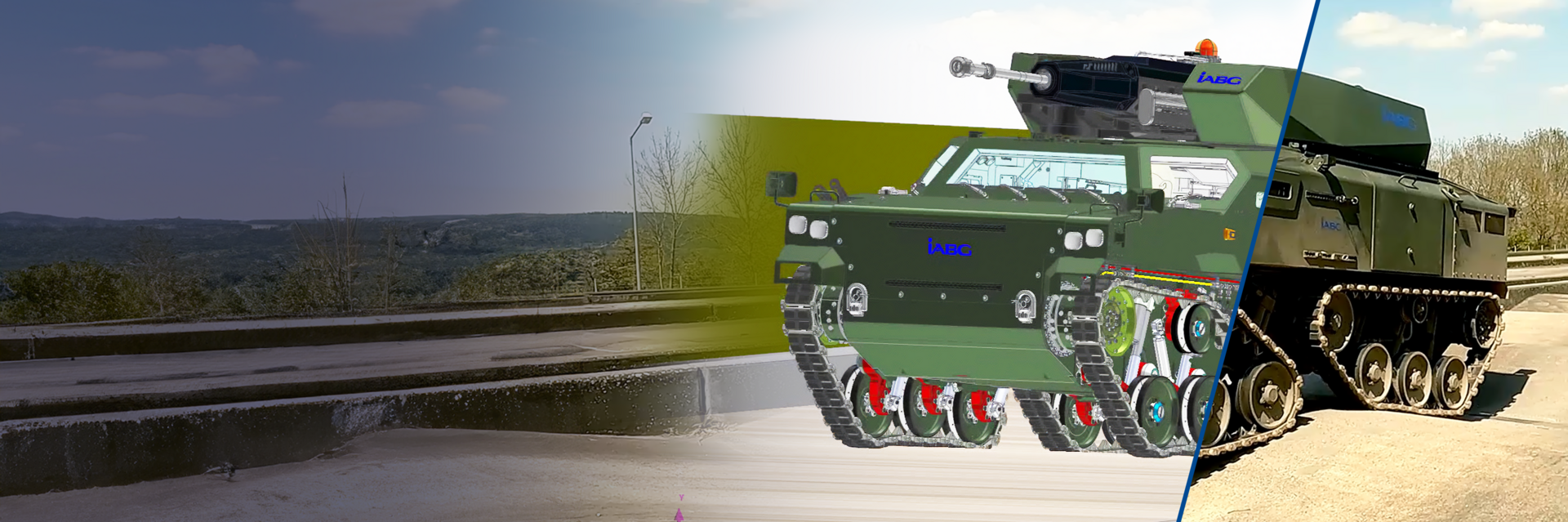

A concrete example of the successful use of this technology is the development of the 'LuWa' (airmobile weapon carrier) overall system demonstrator (GSD). The aim of the project led by IABG is to investigate concepts and technologies for a successor system to the Wiesel 1 weapon carrier. The demonstrator was realized from the idea to final acceptance in just 25 months - a speed that would not have been possible without the digital twin. Thanks to the close coordination of the project partners involved - the German companies ACS and FFG as well as Valhalla Turrets from Slovenia - the armament, propulsion and chassis subsystems were developed independently of each other in parallel and various concepts were examined. The Federal Office of Bundeswehr Equipment, Information Technology and In-Service Support (BAAINBw) was involved in the planning and development status at all times.